In skeleton framing all the gravity loadings of the structure, including the walls are supported by the steel framework. Such walls are termed non-bearing or curtain walls. This system made the skyscraper possible. Steel, being so much stronger

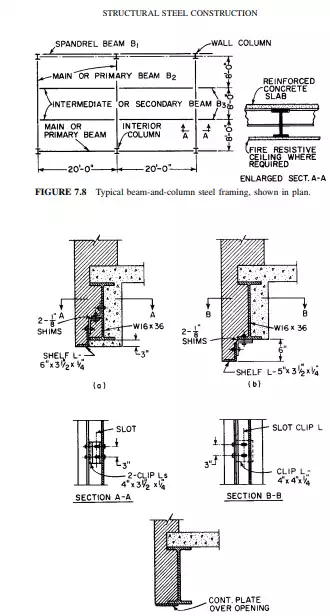

FIGURE 7.9 Typical steel spandrel beams.

than all forms of masonry, is capable of sustaining far greater load in a given space, thus obstructing less of the floor area in performing its function.

With columns properly spaced to provide support for the beams spanning between them, there is no limit to the floor and roof area that can be constructed with this type of framing, merely by duplicating the details for a single bay. Erected tier upon tier, this type of framing can be built to any desired height. Fabricators refer to this type of construction as ‘‘beam and column.’’ A typical arrangement is illustrated in Fig. 7.8.

The spandrel beams, marked B1 in Fig. 7.8, are located in or under the wall so as to reduce eccentricity caused by wall loads. Figure 7.9 shows two methods for connecting to the spandrel beam the shelf angle that supports the outer course of masonry over window openings 6 ft or more in width. In order that the masonry contractor may proceed expeditiously with the work, these shelf angles must be in alignment with the face of the building and at the proper elevation to match a masonry joint. The connection of the angles to the spandrel beams is made by bolting; shims are provided to make the adjustments for line and elevation.

Figure 7.9a illustrates a typical connection arrangement when the outstanding leg of the shelf angle is about 3 in or less below the bottom flange of the spandrel beam; Fig. 7.9b illustrates the corresponding arrangement when the outstanding leg of the shelf angle is more than about 3 in below the bottom flange of the spandrel beam. In the cases represented by Fig. 7.9b, the shelf angles are usually shipped attached to the spandrel beam. If the distance from the bottom flange to the horizontal leg of the shelf angle is greater than 10 in, a hanger may be required.

In some cases, as over door openings, the accurate adjustment features provided by Fig. 7.9a and b may not be needed. It may then be more economical to simplify the detail, as shown in Fig. 7.9c. The elevation and alignment will then conform to the permissible tolerances associated with the steel framework.

Comments are closed.