Wastewater Screening is the first unit operation in all wastewater treatment plants. Screen is the device used to retain solids found in the influent wastewater to the treatment plant. The main purpose of screening is to remove solid materials that could:

· Cause damage to other process equipment.

· Cause reduction in efficiency of the whole system

· Contaminate waterways

The materials that are removed using screens are called screenings.

Screening process in a wastewater treatment system (YouTube.com)

Classification of Wastewater Screens

Screens are generally classified into three based on the size of their openings in the screening element and mechanism of removal.

· Coarse screens

· Fine screens

· Microscreens

Coarse screens

Coarse screens have a clear openings ranging from 6 to 150 mm (0.25 t0 6 in). Coarse screen consist of parallel bars, rods or wires, wire mesh or a perforated plates with openings generally of circular or rectangular shapes. So it is also call as “bar rack” and used to remove coarse solids such as rags and large objects that may clog or cause damage to other appurtenances. Based on the Wastewater Screening method used to clean them, coarse screens are classified into two:

· Hand cleaned screens

· Mechanically cleaned screens

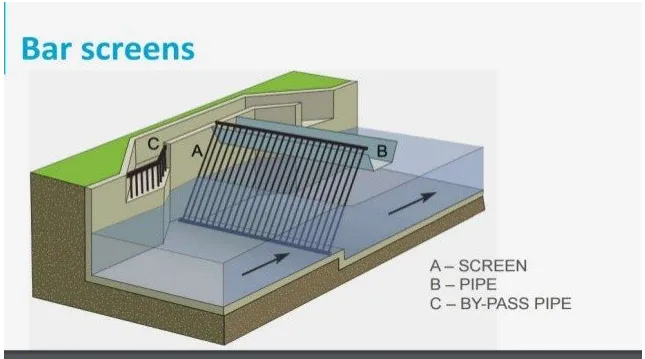

Bar screens (Slideshare)

Hand cleaned coarse screens

Hand cleaned coarse screens are used in small wastewater pumping stations. They are often used as standby screens in bypass channel for service during high-flow periods or when mechanically cleaned screens are under repair or when power failure occurs. When used the length of bar rack should be limited to 3 m, which enables convenient hand raking. The screen channels should be designed in such a way that to prevent excessive accumulation of grit and other heavy metals. The channel should have a straight approach which should be perpendicular to the bar screen to promote uniform distribution of the solids throughout the flow and on the screen.

Mechanically cleaned screen

It is designed mainly to reduce the operating and maintenance problems and to increase the efficiency of screening. Mechanically cleaned bar Wastewater Screens are classified into four principal types:

1. Chain driven screens: this type of screens used a automatic chain to clean the screen. It is classified into front and back chain driven screens on the basis of how the screen is raked from the upstream or in downstream and whether the rakes return to the bottom of the bar screen from the front or back

2. Reciprocating rake (Climber screen): In this type of screen the rake moves to the base of the screen, engages the bars and pulls the screenings in to the top of the screen where they removed. This screen uses only one rake instead of multiple rakes that are used in other type of screens. Due to this they have limited capacity in handling heavy screening loads.

3. Catenary screen: They have the rake which is held against the rack by the weight of chain. They are front cleaned, front return chain driven screen. If heavy objects become jammed in between the bars, the rakes will pass over them instead of further jamming in it.

4. Continuous belt screen: It is a continuous, self cleaning screen that can remove fine and coarse solids. A large number of rakes are attached to the drive chains. The number of screening elements generally depends on the depth of the screen channel.

Mechanically cleaned screens (Mojan engineering)

Fine screens

In Wastewater Screening, Fine screens have clear openings less than 6 mm. They consisted of perforated plates, wire cloth, wedge wire elements that have smaller openings. They are also used to remove the fine solids present in the primary effluent. Fine screens are classified as:

· Static (fixed) wedge wire screen

· Rotary drum screen

· Step type screen

Static wedge wire screens

They have a clear opening of 0.2 to 1.2 mm and designed for a rate of flow of 400 to 1200 L/m2 min of screen area. Large floor area should require for installation of these screens and these should be cleaned once or twice daily.

Drum screens

In this type the screening or straining medium is mounted on a cylinder that rotates in the flow channel. The wastewater flows into either end of drum and flows out through the screen outlet with the solids are being collected on this interior or into the top of the unit.

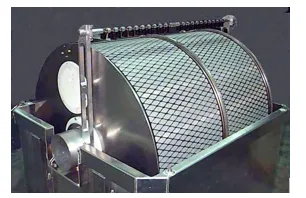

Rotating drum fine screens (Allegri Ecologia)

Step screens

It consists of two step shaped sets of thin vertical plates, one fixed and other one is movable. The fixed and movable step plates alternate across the width of channel and together form a single screen face. The movable plate rotates in a vertical motion. Through this the solids collected on the screen face is lifted up to the next fixed step landing and transported to the top of the screen to discharge into outlet.

Microscreen (Sound engineering)

Microscreens Wastewater Screening

They are rotating drum screens which have a variable low speed (upto 4 r/min), which is continuously backwashed operating in gravity flow conditions. The filtering fabrics used should have a openings ranges from 10 to 35µm and fitted on the periphery of the drum. The influent enters through drum lined with fabric. The solids retained are collected through backwashing and transported for disposal.