Glass is so widely used for decorative and utilitarian purposes in modern construction that it would require an encyclopaedia to list all the varieties available. Clear glass for windows and doors is made in varying thicknesses or strengths, also in double layers to obtain additional thermal insulation. Safety glass, laminated from sheets of glass and plastic, or made with embedded wire reinforcement, is available for locations where breakage might be hazardous. For ornamental work, glass is available in a wide range of textures, colours, finishes, and shapes.

Window Glass

Various types and grades of glass are used for glazing:

Clear Window Glass. This is the most extensively used type for windows in all classes of buildings. A range of grades, as established by Federal Government Standard DD-G-451c, classifies quality according to defects. The more commonly used grades are A and B. A is used for the better class of buildings where appearance is important, and B is used for industrial buildings, some low-cost residences, basements, etc.

With respect to thickness, clear window glass is classified as ‘‘single-strength’’ about 3 ⁄32 in thick; ‘‘double-strength,’’ about 1 ⁄8 in thick; and ‘‘heavy-sheet,’’ up to 7 ⁄32 in thick. Maximum sizes are as follows: single-strength, 40 x 50 in; double strength, 60 x 80 in; and heavy sheet, 76 x 120 in. Because of flexibility, single strength and double strength should never be used in areas exceeding 12 ft2 , and for appearance’s sake areas should not exceed 7 ft2 .

Plate and Float Glass.

These have, in general, the same performance characteristics. They are of superior quality, more expensive, and have better appearance, with no distortion of vision at any angle. Showcase windows, picture windows, and exposed windows in offices and commercial buildings are usually glazed with polished plate or float glass. Thicknesses range from 1 ⁄8 to 7 ⁄8 in. There are two standard qualities, silvering and glazing, the latter being employed for quality glazing.

Processed Glass and Rolled Figured Sheet.

These are general classifications of obscure glass. There are many patterns and varying characteristics. Some provide true obscurity with a uniform diffusion and pleasing appearance, while others may give a maximum transmission of light or a smoother surface for greater cleanliness. The more popular types include a clear, polished surface on one side with a pattern for obscurity on the other side.

Obscure Wired Glass.

This usually is specified for its fire-retarding properties, although it is also used in doors or windows where breakage is a problem. It should not be used in pieces over 720 in2 in area (check local building code).

Polished Wired Glass.

More expensive than obscure wired glass, polished wired glass is used where clear vision is desired, such as in school or institutional doors. There are also many special glasses for specific purposes:

Heat-Absorbing Glass.

This reduces heat, glare, and a large percentage of ultraviolet rays, which bleach colored fabrics. It often is used for comfort and reduction of air-conditioning loads where large areas of glass have a severe sun exposure. Because of differential temperature stresses and expansion induced by heat absorption under severe sun exposure, special attention should be given to edge conditions. Glass having clean-cut edges is particularly desirable, because these affect the edge strength, which, in turn must resist the central-area expansion. A resilient glazing material should be used.

Corrugated Glass, Wired Glass, and Plastic Panels.

These are used for decorative treatments, diffusing light, or as translucent structural panels with colour.

Laminated Glass.

This consists of two or more layers of glass laminated together by one or more coatings or a transparent plastic. This construction adds strength. Some types of laminated glass also provide a degree of security, sound isolation, heat absorption, and glare reduction. Where colour and privacy are desired, fadeproof opaque colours can be included. When fractured, a laminated glass tends to adhere to the inner layer of plastic and, therefore, shatters into small splinters, thus minimizing the hazard of flying glass.

Bullet-Resisting Glass.

This is made of three or more layers of plate glass laminated under heat and pressure. Thicknesses of this glass vary from 3 ⁄4 to 3 in. The more common thicknesses are 13 ⁄16 in, to resist medium-powered small arms: 11 ⁄2 in, to resist high-powered small arms; and 2 in, to resist rifles and submachine guns. (Underwriters Laboratories lists materials having the required properties for various degrees of protection.) Greater thicknesses are used for protection against Armor piercing projectiles. Uses of bullet-resisting glass include cashier windows, bank teller cages, toll-bridge booths, peepholes, and many industrial and military applications. Transparent plastics also are used as bullet-resistant materials, and some of these materials have been tested by the Underwriters Laboratories. Thicknesses of 11 ⁄4 in or more have met UL standards for resisting medium-powered small arms.

Tempered Glass.

This is produced by a process of reheating and sudden cooling that greatly increases strength. All cutting, and fabricating must be done before tempering. Doors of 1 ⁄2- and 3 ⁄4-in-thick tempered glass are commonly used for commercial building. Other uses, with thicknesses from 1 ⁄8 to 7 ⁄8 in, include backboards for basketball, showcases, balustrades, sterilizing ovens, and windows, doors, and mirrors in institutions. Although tempered glass is 41 ⁄2 to 5 times as strong as annealed glass of the same thickness, it is breakable, and when broken, disrupts into innumerable small fragments of more or less cubical shape.

Tinted and Coated Glasses.

These are available in several types and for varied uses. As well as decor, these uses can provide for light and heat reflection, lower light transmission, greater safety, sound reduction, reduced glare, and increased privacy.

Transparent Mirror Glass.

This appears as a mirror when viewed from a brightly lighted side and is transparent to a viewer on the darker opposite side. This one way-vision glass is available as a laminate, plate or float, tinted, and in tempered quality.

Plastic Window Glazing.

Made of such plastics as acrylic or polycarbonate, plastic glazing is used for urban school buildings and in areas where high vandalism might be anticipated. These plastics have substantially higher impact strength than glass or tempered glass. Allowance should be made in the framing and installation for expansion and contraction of plastics, which may be about 8 times as much as that of glass. Note also that the modulus of elasticity (stiffness) of plastics is about one-twentieth that of glass. Standard sash, however, usually will accommodate the additional thickness of plastic and have sufficient rabbet depth.

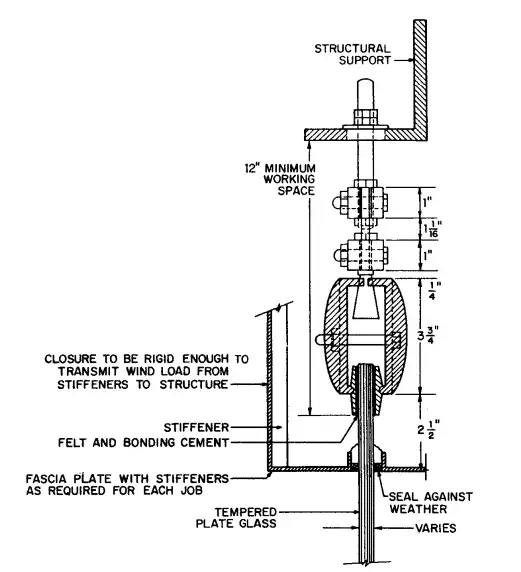

Suspended Glazing.

This utilizes metal clamps bonded to tempered plate glass at the top edge, with vertical glass supports at right angles for resistance to wind pressure (Fig. 4.1). These vertical supports, called stabilizers, have their exposed edges polished. The joints between the large plates and the stabilizers are sealed with a bonding cement. The bottom edge or sill is held in position by a metal channel and sealed with resilient waterproofing. Suspended glazing offers much greater latitude in use of glass and virtually eliminates visual barriers.

Safety Glazing.

A governmental specification Z-97, adopted by many states, requires entrance-way doors and appurtenances glazed with tempered, laminated, or plastic material.

Glass Block

Glass blocks are made by first pressing or shaping half blocks to the desired form, then fusing the half blocks to form a complete block. A block is usually 37 ⁄8 in thick and 53 ⁄4, 73 ⁄4, or 113 ⁄4 in square. The center of the block is hollow and is under a partial vacuum, which adds to the insulating properties of the block. Corner and radial blocks are also available to produce desired architectural effects.

Glass block is commonly laid up in a cement or a cement-lime mortar. Since there is no absorption by the block to facilitate bond of mortar, various devices are employed to obtain a mechanical bond. One such device is to coat the sides of the block with a plastic and embed therein particles of sand. The difficulty in obtaining permanent and complete bond sometimes leads to the opening up of mortar joints. A wall of glass block, exposed to the weather, may leak badly in a rainstorm unless unusual precautions have been taken during the setting of the block to obtain full and complete bond.

Glass blocks have a coefficient of thermal expansion that is from 11 ⁄2 to 2 times that of other masonry. For this reason, large areas of block may expand against solid masonry and develop sufficient stress so that the block will crack. Manufacturers usually recommend an expansion joint every 10 ft or so, to prevent building up of pressure sufficient to crack the block. With adequate protection against expansion and with good workmanship, or with walls built in protected locations.

FIGURE 4.1 Typical details of suspended glazing.

glass-block walls are ornamental, sanitary, excellent light transmitters, and have rather low thermal conductivity.

WOOD

Wood is a building material made from trees. It is a natural polymer composed of cells in the shape of long, thin tubes with tapered ends. The cell wall consists of cellulose crystals, which are bonded together by a complex amorphous lignin composed of carbohydrates. Most of the cells in a tree trunk are oriented vertically. Consequently, properties of wood in the direction of cell axes, usually referred to

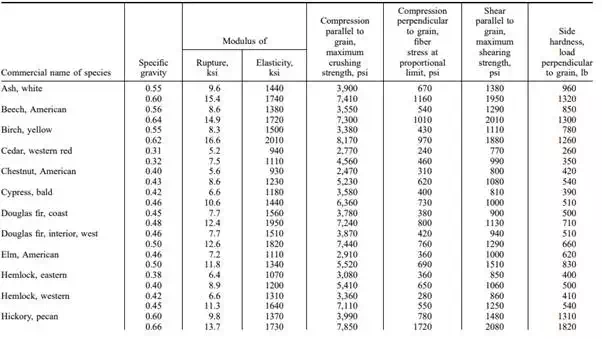

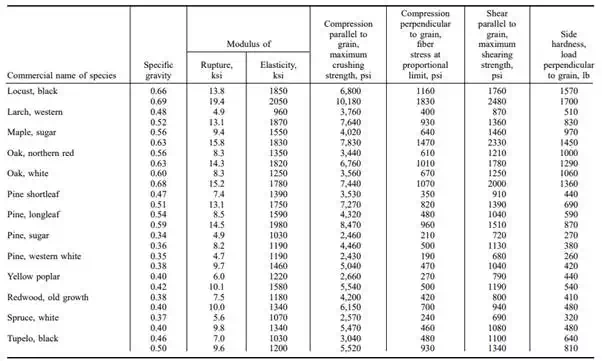

TABLE 4.14 Strength of Some Commercially Important Woods Grown in the United States*

TABLE 4.14 Strength of Some Commercially Important Woods Grown in the United States*

as longitudinal, or parallel to grain, differ from those in the other (radial or circumferential) directions, or across the grain.