Bolt is a metal pin with a head at one end and a shank threaded at other end to receive a nut, as shown in Figure.

BOLTED CONNECTIONS

Bolt is a metal pin with a head at one end and a shank threaded at other end to receive a nut, as shown in Figure 6. Steel washers are usually provided under the bolt head and nuts to prevent the treaded portion of the bolt from bearing on the connecting pieces and to distribute the clamping pressure on the bolted member.

A bolt connection can be used for end connections in tension and compression members. They can also hold down column bases in position and as separator for purlins and beams in foundations. Bolts are having the following advantages over rivets and pins: (a) the erection of the structures can be speeded up. (b) Less skilled labour can be employed. (c) Overall cost of bolted connection is lesser than the other alternatives. However the following shortcomings are also associated with the bolted connections: (a) Cost of material is high, about double than that of rivets. (b) The tensile strength of bolt is reduced due to the reduced area at the root of the thread and stress concentration. (c) Normally strength reduction will be there for loose fit bolts. (d) Bolts may get loose when subjected to vibrations.

CLASSIFICATIONS OF BOLT CONNECTIONS

Bolt connections are generally classified in the following ways

1. Based on the resultant force transferred.

Bolt connections can be classified in to the following heads based on how the resultant force transferred at the joint. (a) Concentric connection – if the force transferred passes through the CG of the connection. Eg. Axially loaded compression and tension members. (b) Eccentric connection – if the load is not passing through the CG of the connection. Eg. Bracket connection and seat connection.

(c) Moment resisting connection – when the joints are subjected to moments. Eg. Beam to column connection in framed construction.

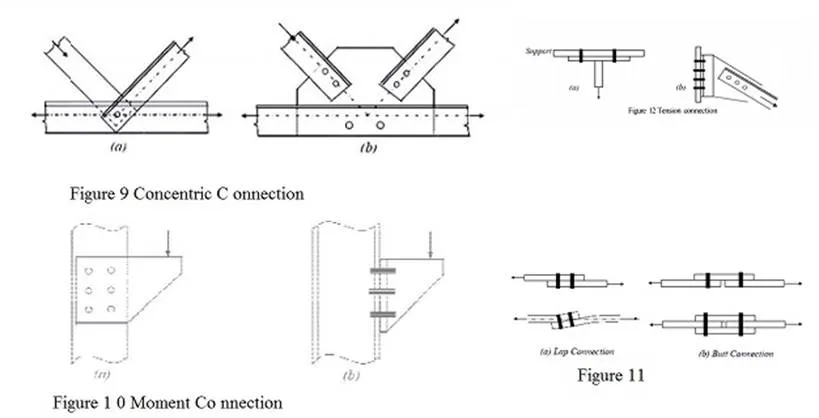

Ideal concentric connections should have only one bolt passing through all the members meeting at a joint as shown in Figure 9(a). However, in practice, this is not usually possible and so it is only ensured that the centroidal axes of the members meet at one point as shown in Figure 9(b).

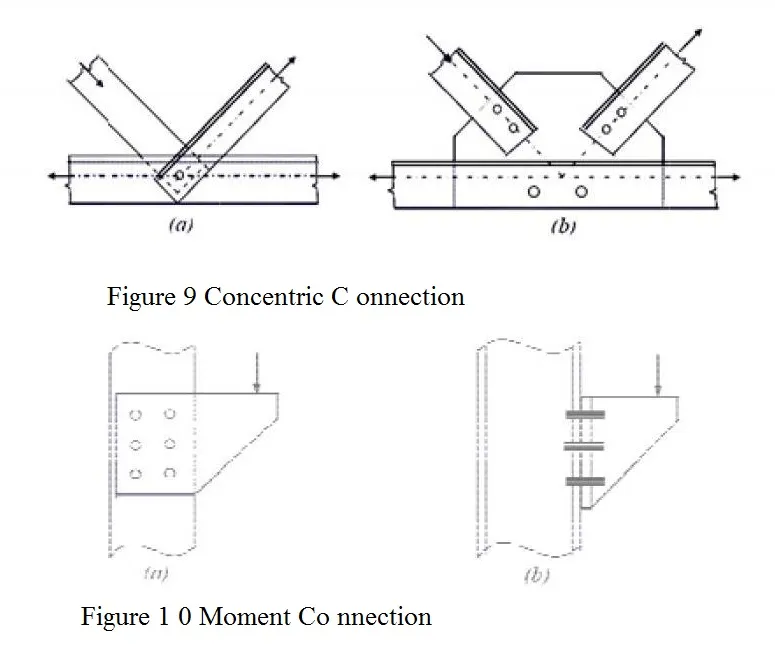

The Moment connections are more complex to analyse compared to the above two types and are shown in Figure 10(a) and Figure 10(b). The connection in Figure 10(a) is also known as bracket connection and the resistance is only through shear in the bolts. The connection shown in Figure 10(b) is often found in moment resisting frames where the beam moment is transferred to the column. The connection is also used at the base of the column where a base plate is connected to the foundation by means o f anchor bol ts. In this co nnection, th e bolts are subjected a combinati on of shear and axial to tensi.

2. B ased on the type of force

Bolt connections can be classified in to the following based on the type of force transferred:

(a) Shear connection – when the load transfer is through shear. Eg. Lap joint and tension joint;

(b) Tension joints – when load is transferred by tension in the bolts. Eg. Hanger connection;

(c) Combined shears and tension connections – when load is transferred through the combinations of shear and tension. Eg. Inclined members connected to columns or beams.

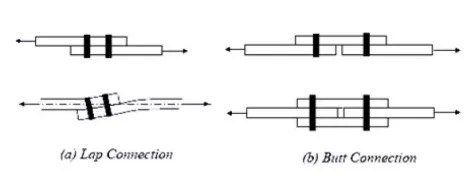

Typical shear connections occur as a lap or a butt joint used in the tension members as shown in Figure 11. While the lap joint has a tendency to bend sothat the forces tend to become collinear, the butt joint requires cover plates. Since the load acts in the plane of the plates, the load transmission at the joint will ultimately be through shearing forces in the bolts.

In the case of lap joint or a single cover plate butt joint, there is only one shearing plane, and so the bolts are said to be in single shear. In the case of double cover butt joint, there are two shearing planes and so the bolts will be in double shear. It should be noted that the single cover type butt joint is nothing but lap joints in series and also bends so that the centre of the cover plate becomes collinear with the forces. In the of single cover plate (lap) joint, the thickness of the cover plate is chosen to be equal to or greater than the connected plates. While in double cover plate (butt) joint, the combined thickness of the cover plates should be equal to or greater than the connected plates.

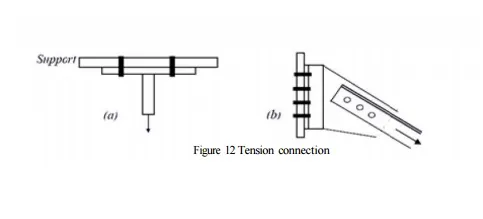

A hanger connection is shown in Figure 12(a). In tension in the bolts. In the connection shown in Figure and shear.

this connection, load transmission is by pure 12(b), the bolts are subjected to both tension

3. On the basisof force transfer mechanism

Bolt connections are classified into the following based on the way in which load is transferred from one member to another connected in the joint.

(a) Bearing type- bolts bears against the holes to transfer the load from one member to another. Eg. Slip type connection.

(b) Friction type – when the force is transferred by friction between the plates due to tensioning of bolts. Eg. Slip-critical connects.

Comments are closed.